Quote from: sqlbullet on November 27 2017 05:03:10 PM MST

That is how you check tension, but tension is not your problem. Fitting is.

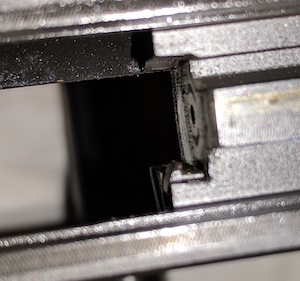

Picture is worth 1K words:

This is mine as it came from the factory. Lots of three point jams, just like you describe.

See how the lower edge of the extractor hangs out past the slide? That edge needs to be broken and smoothed so the rim of the case won't catch on it as it rides up under the extractor hook. I removed mine, put a file to it, and then some 400 grit, then some 800 grit. When I was done it would hand cycle dummy rounds. I have not made it back to the range yet.

If you extractor doesn't hang out like this, it may not be your issue, but I am betting this is it.

Other possibilities: Rough breech face, bad magazine springs, rough feedramp/throat and stem bind.

As this is a new gun and we haven't had reports from other RIA owners about issues related to the breech face, feed ramp/throat or magazine springs, I bypassed these. I actually bypass them for two reason. First, no reports, as mentioned. Second, with the exception of magazine springs, I think polishing breech faces and ramps is a short term fix to a bigger problem. See, I want a gun to function even if it gets dirty and scroungy in the breech face/feed ramp area.

This leaves us with extractors that are poorly fit, though properly tensioned, or with a link pin and lower lug that need some work.

And most guys report extractors that look about like mine did above. And that once they address the extractor, the issues go away.

Here is a Wilson Combat video about the issue:

AWESOME info.